How to choose the right Tread Pattern for your truck/bus tyre?

Tyres are an indispensable part of a commercial vehicle; they carry the load and maneuvers the vehicle on roads. Tyres come in direct contact with the road, face sharp stones, trudge through trenches, cut through the water, tolerate scorching heat, and whatnot.

You must have had some experience with tyres, do they all look the same.? No, each tyre is uniquely designed to fulfill a specific purpose. Some tyres are designed to perform on snow, Some tyres will help navigate through the mountains, some can survive in mines, and others run on highways at high speed and load.

So how do we choose the right tyre and the right tread rubber? To make the right choice, we first need to understand the construction of a truck/bus tyre and the factors affecting the tyre choice.

A. Understand your truck/bus tyres comprehensively

We can know a tyre by understanding two major parts of it- One is its carcass construction, and the other is its tread design.

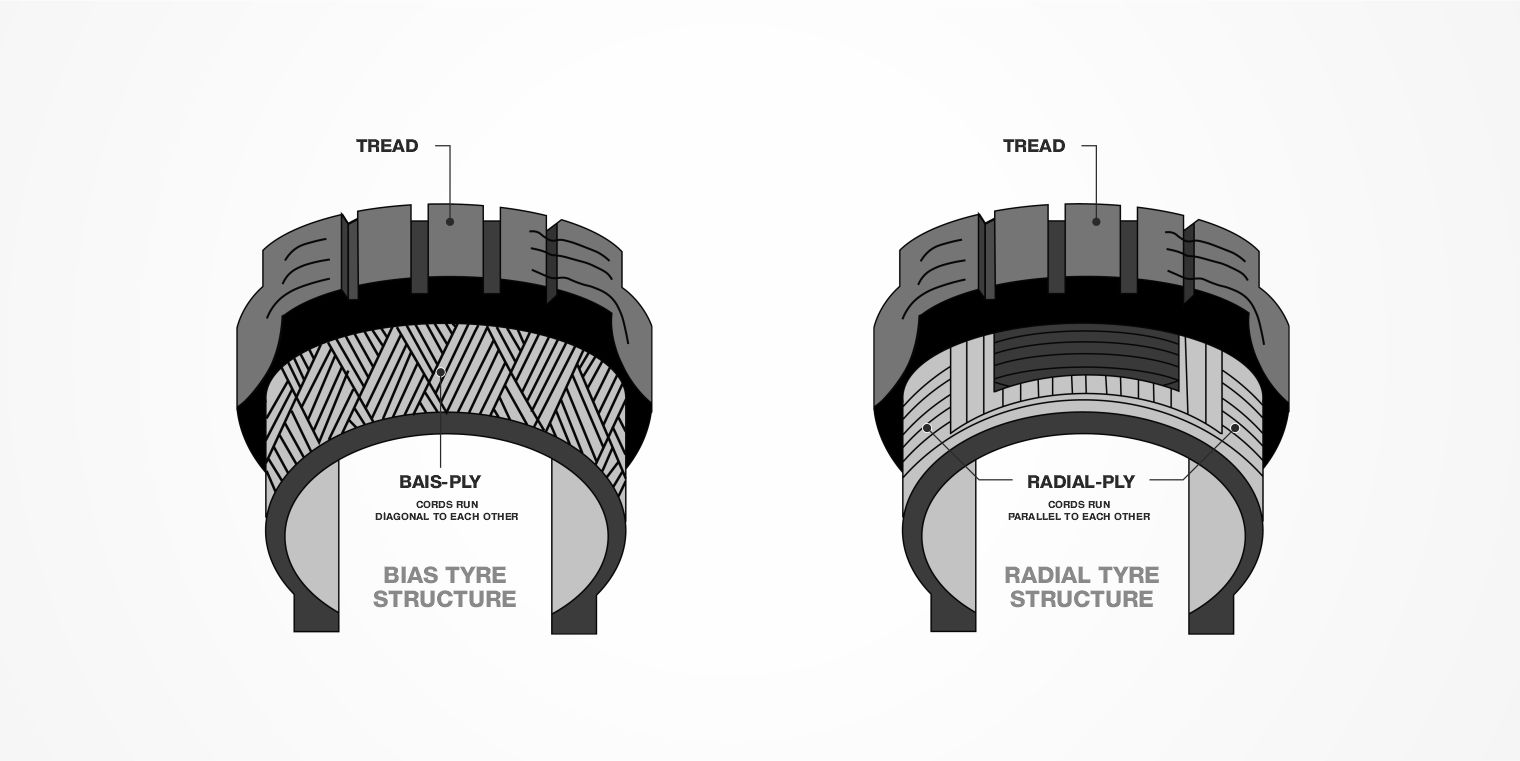

1. Tyre carcass construction- A tyre carcass is constructed with a set of plies placed in a specific order; these plies are either made from nylon or steel. There rea two types of tyres based on their carcass construction

-

Bias tyre- In a Bias tyre the nylon belts run at 30 to 45-degree angles with the tread line. The multiple, overlapping rubber plies in these tyres connect the sidewall and tread.

-

Advantages-

-

Bias ply is accompanied by a tougher sidewall that makes it very successful on unpaved & rough roads.

-

The Bias tyres are cheaper as compared to Radial tyres in terms of upfront cost.

-

-

Disadvantages-

-

Bias tyres have a curvature on their crown surface area( tread area that meets the road), due to which the contact area with the road is smaller and the load distribution per unit area is higher

-

This results in quick abrasion of the tread rendering a low mileage output. The low mileage when distributed on the upfront cost of the tyre, the CPKM for bias tyre comes out to be very high.

-

2. Radial Tyres- In Radial tyres, the steel belts run at a 90-degree angle with the tread line. It enables the tread and the sidewall of the tyre to function independently of each other.

-

Advantages-

-

Radial tyres have a flat tread area and have a much larger contact area with the road, the load distribution is more uniform, and the mileage achieved is about twice of a bias tyre. This makes the CPKM of radial tyres relatively lower than that of bias tyres.

-

-

Disadvantages-

-

They are more expensive than bias tyres in terms of upfront cost.

-

The sidewall of radial tyres is not so stiff and more prone to cuts and damages. Thus, radial tyres often fail on rough or unpaved roads.

-

2. Tyre tread design- The tread designs are carefully crafted by a team of engineers to meet the specific needs of a fleet owner. Broadly we have three categories of tyres based on the design patterns-

-

Rib: In this design pattern, multiple side-by-side ribs are typically moulded in a continuous strip of tread rubber around a tire's circumference.

-

The continuous strips help the tyre make quick movements on turns and make the tyre a suitable choice for maneuvering the vehicle. Hence, it is recommended for the steering axle of a vehicle.

2. Lug: It is a design with freestanding and extra-large lugs positioned across the tyre's circumference.

-

It lugs positioned across the tyre's circumference give better traction to the tyre and thus recommended for the drive axle.

3. Semi-Lug: As the name suggests, it is a mix of both Rib and Lug patterns, rib part takes the center, and lugs reside on the shoulder.

-

The central rib part provides good directional control, and the shoulder lugs offer good braking & driving power. It is suitable for dummy axles and can also be used in both drive and steer axle in some special cases.

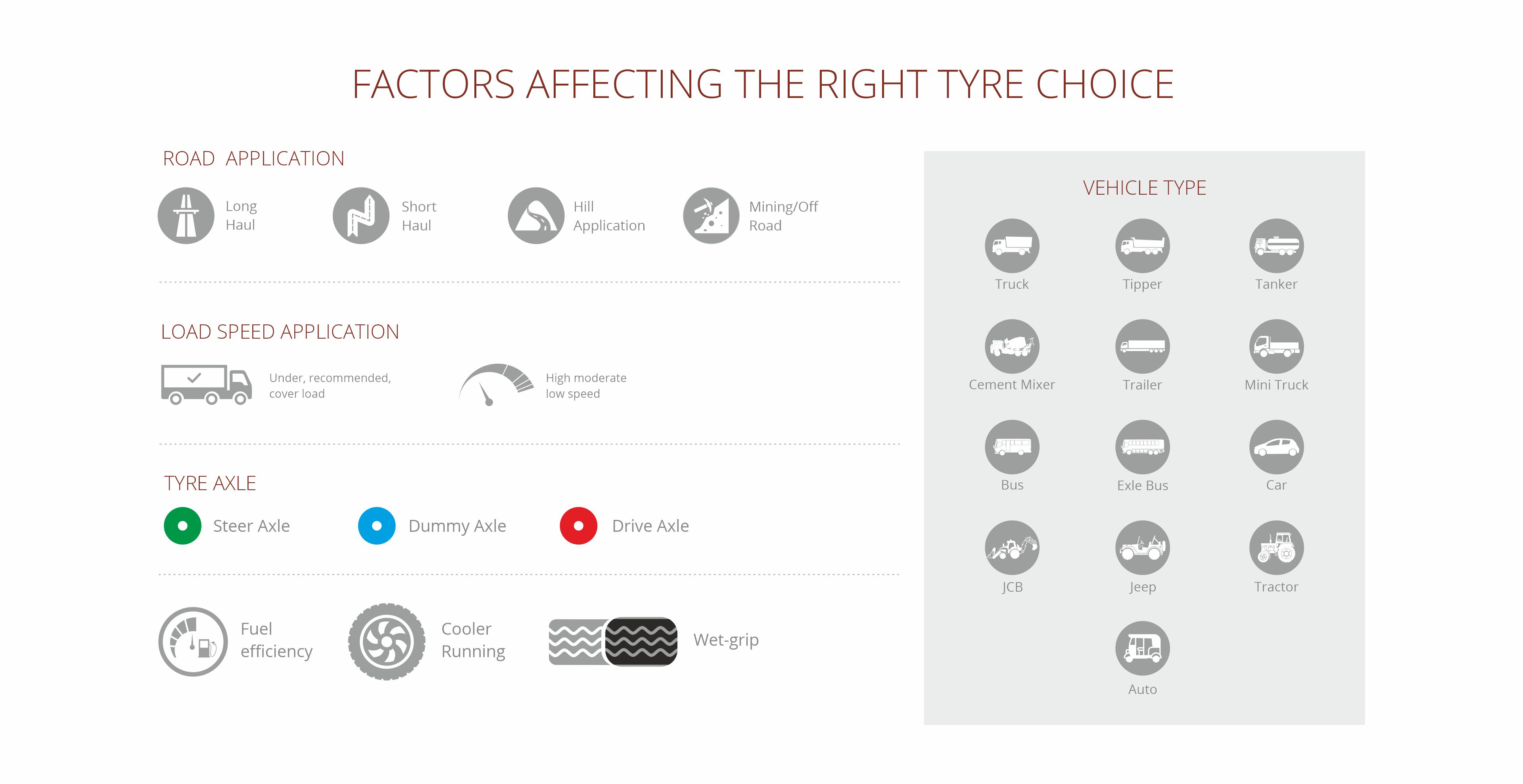

B. Understand the factors that affect a tyre choice-

Now, as we are clear about the construction of a tyre and its tread design, we can make a choice of a tyre by understanding our needs. The tyre choice can be affected by a long list of factors. Some of the key factors are discussed here-

-

Road application- In a country like India, we have all kinds of roads and terrains- Hilly areas, high-speed highways, unpaved /kaccha roads, mines, city roads, a mix of good, bad roads, wet roads, and many others. Each road application will require a specific design pattern and ply construction to give optimum performance. Example-In mines bias tyres with a stronger sidewall provide better protection against sharp objects as compared to radial tyres.

-

Speed & Load application- High speed or high load causes high heat generation tyre, so cooler running tyres can be preferred with wider grooves in tread design. The high load can be compensated by higher ply rating casings with more strength

-

Tyre axle- Each axle has a role to play in moving a vehicle smoothly. Drive axle has to give enough traction to balance engine torque, the steer axle needs to be quick at manoeuvring the vehicle, and dummy axle needs to carry the load without impeding vehicle movement. So, a rib is preferred on the steer axle, a lug is preferred on the drive, and a semi-lug on the dummy.

-

Vehicle type- No one tyre fits all vehicles. Each vehicle is designed for fulfilling a set of specific tasks. A trailer will have multiple dummy axles and requires the least impediment in vehicle movement; thus rib patterns are used, while a mixer or a tanker might use a lug in its dummy axle because the nature of their business requires more traction.

-

Fuel efficiency- Fuel constitutes the biggest share of the operating cost of any commercial vehicle. It is also affected by the type of tyre you use; a tyre with low rolling resistance gives better fuel efficiency. The rubber compound formula and tread design both play an important part in deciding the rolling resistance of a tyre.

Note: It is imperative to know that in most cases, no one factor but combinations of the above factors play a deciding role in choosing the right tyre for your vehicle.

C. How should you choose the right tread for your tyre?

Once you are well versed with the tyre construction and factors affecting the selection of tyres, choosing a tread rubber pattern is not so daunting. Before making a choice of the right tread pattern, we need to understand that tread pattern has two major parts to it-Tread Design pattern and the Tread rubber compound.

1. How to choose the right design pattern

-

Understand the type of casing you have-Bias or Radial. The tread design patterns for bias and radial tyres are completely different, e.g., Radial patterns are generally made up of small, dense blocks as the tread surface in contact with the road is higher.

-

Be sure of the tyre axle you want to put the retreaded tyre on. Based on the tyre axle, choose the right tread design type- Rib, Lug or Semi-ug

-

Once the tyre type, the tread type and the tyre axle are sorted, we need to filter it further down based on the vehicle type and the road application

-

Analyzing the features & advantages of each filtered design pattern carefully, choose the fittest tread pattern. Example- Tread design with wide groves gives better airflow and cooler running, suitable for vehicles plying on longer distances and high load-high speed application.

-

You can also refer to the tread finder in the top right corner of our header to find the right tread for your tyres.

2. How to choose the right tread rubber compound

Tread rubber compound is a special formulation used to enhance vital tread properties. It affects certain performance parameters of the tread rubber such as rolling resistance( responsible for fuel efficiency), cut-chip resistance, wet-grip, mileage(No. of Kms), cooler running, traction, etc. Based on your needs, you must choose the right formulation for optimum performance outputs.

-

If you are looking for a tread pattern that performs well under the high load-high speed application and on long continuous voyages, then you must choose the tread compound with cooler running and high tensile strength.

-

Similarly, if your focus is on the fuel efficiency of the tread rubber, then you must side with a formulation of low rolling resistance.

-

For road applications like mines where the tread rubber is exposed to sharp stones, choose a compound that has very high cut-chip resistance.

-

Please note that not all properties cannot be imbibed in a single tread compound; to accentuate one property of the tread rubber, we have to compromise on other properties.

We at Indag understand the importance of choosing the right tread pattern and the compound for an optimum performance output from retreaded tyres. We help our customers choosing the tread pattern through our Tread Finder and a range of tread rubber brands, each designed to cater to the specific needs of fleet owners. To learn about each brand in detail, kindly contact us. We will help you by answering all appropriate questions.