URSGINDAG BONDING GUM

SALIENT FEATURES

- . Super strong bonding

- . High stretchability

- . Rapid rate of bond formation

- . Maximum green tack

- . Uniform curing

- . No tread lifting

- . More mileage

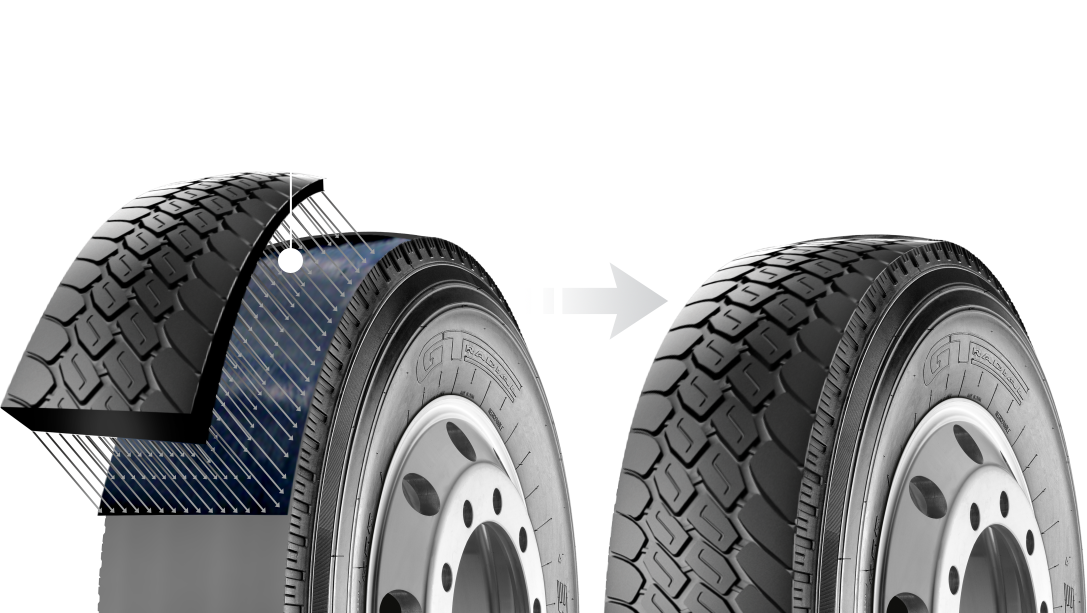

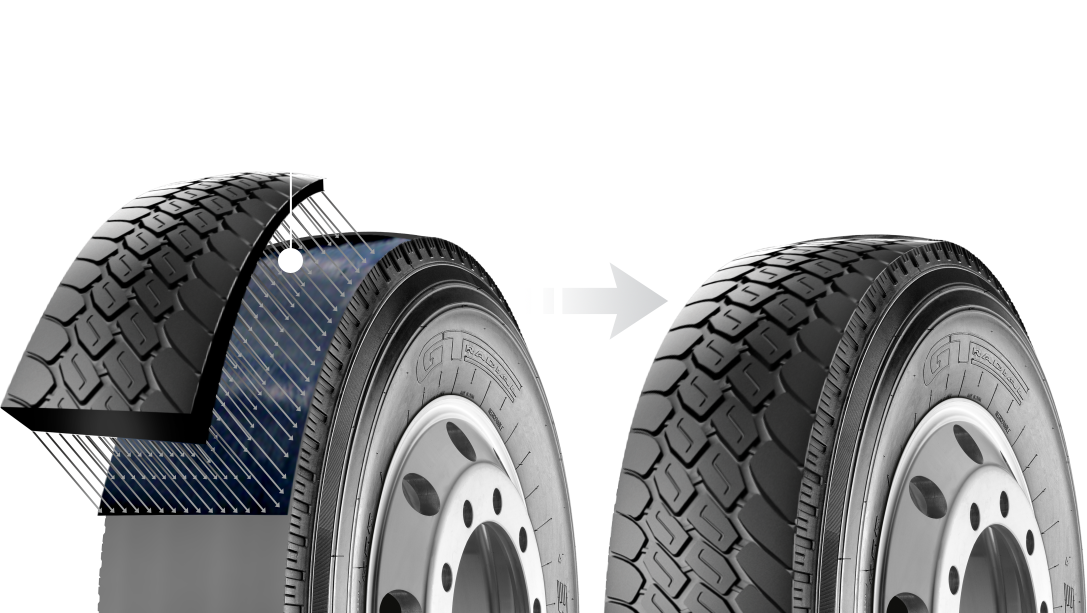

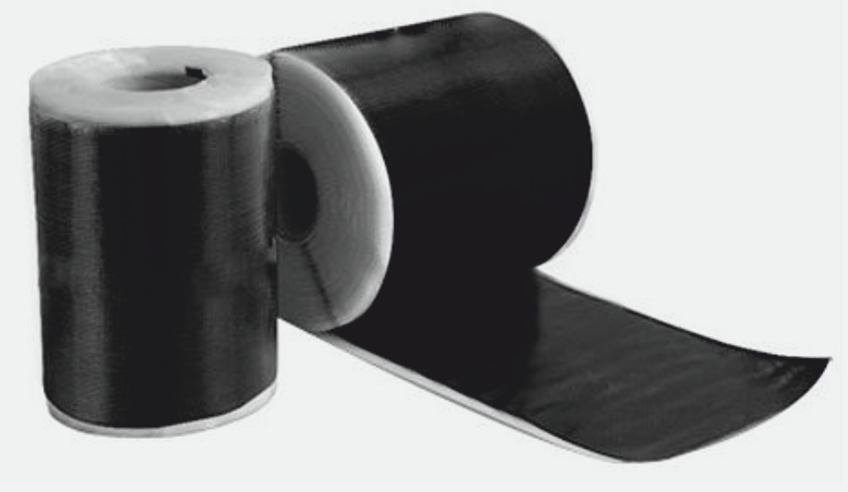

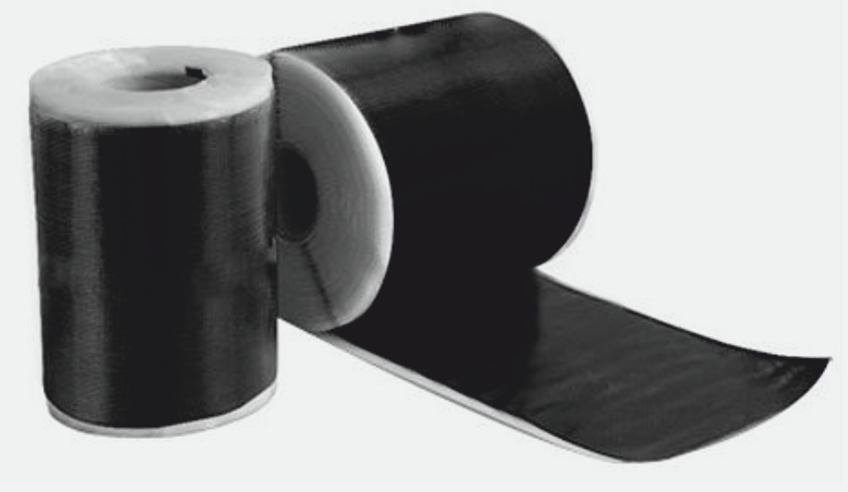

The Unvulcanized Rubber Strip Gum (URSG) or cushion/bonding gum is a critical component used in the retreading process. It is used as an adhesive between the vulcanized tread (PTR) and the tyre casing which is vulcanized in the retreading process. The quality of URSG decides the strength of the bond between pre-cured tread rubber and tyre casing, low quality URSG renders weak bonds, which lead to separation between casing and PTR and results to a tyre failure. Based on different market needs we have a range of products in the URSG category- IN30, IN 40 & IN50, details are shared below-

To be used for chamber only

Recommended for chamber

Recommended for both chamber & bonder