It cannot be emphasized more that retreading is a highly technical process and requires the best quality retreading materials and an impeccable retreading process. In India, retreading is gravely challenged for its safety and performance against new tyres. Our retread partners battle these challenges every day to strengthen the fleet owners’ confidence in retreading.

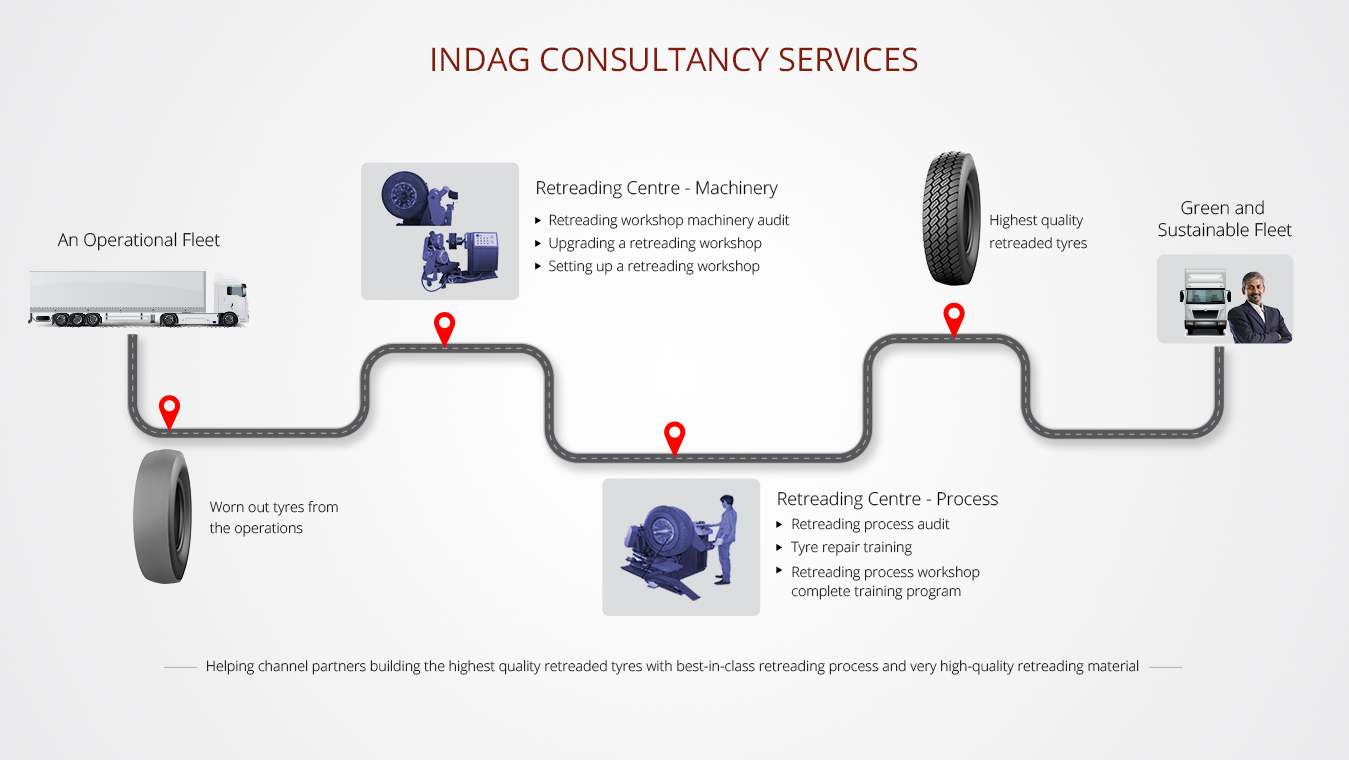

We have designed INDAG Consultancy Services to help our retread partners win this battle. We extend the following services under this program-

1. Retreading Process Consultancy- The objective of this service is to educate our retread partners on the correct retreading practices and impart hands-on training. 2. Retreading Machinery Consultancy- Due to its technical nature, retreading output is highly dependable on the machinery prowess. We audit the machinery of our retread partners at their workshops, also help them upgrade or set up the retreading workshops. 3. Troubleshooting- Accidents can always happen; there can be a machinery breakdown or a retread failure, jeopardizing the functioning of the workshop. In such emergencies, we provide on-demand troubleshooting services to help our retread partners resolve the problem.

Retreading is a green and sustainable alternative to new tyres, it allows fleet owners to reuse their old tyres. Nonetheless, it has its own challenges, it is often surrounded by myths about its safety and quality against new tyres.

Scientifically, it is well established that retreaded tyres are as safe as new tyres, but sometimes the lack of using the correct retreading process results in a retread failure. Such incidents mar the reputation of retreading against new tyres.

We at INDAG are committed to helping our fleet owners fostering their trust in retreading and we take it as our responsibility to train all our retread partners in the correct retreading process.

To fulfill this objective, we have designed INDAG’s 10-step retreading process, a renowned and successful process with the legacy of revolutionizing the Indian retreading industry. We organize retreading process workshops and train our retread partners from time to time on INDAG’s 10-step retreading process.Following are the key elements of the Retreading process workshop:

Expert training on INDAG's 10 step retreading process

Expert training on INDAG's 10 step retreading process Application of different retreading materials

Application of different retreading materials Troubleshooting- Retread Failures

Troubleshooting- Retread FailuresAnalyze the problem behind retread failure based on below factors and troubleshoot it

Tyre repair training

Tyre repair trainingLearn to repair tyres based on their construction-

INDAG Retreading Certification

INDAG Retreading CertificationGet your retreading team certified by INDAG retreading experts

With the changing times, Indian commercial tyre industry is also changing. We are witnessing the industry shifting towards complete radialization, with tubeless tyres also making their way in.

Repairing is a key process in retreading a tyre. Even the slightest mistake in repairing can result in the complete failure of a retreaded tyre.

Thus, it is imperative that workers at any retreading or repair shop are well trained in repairing all types of tyres. To repair a bias and a radial tyre, one needs to have different sets of tools and follow separate processes. Similarly, repairing a tubeless tyre is quite different from repairing a tube tyre.

At INDAG, we emphasize on training our retread partners in repairing different types of tyres under our retreading Process Consultancy services. It ensures that the best repairs are made, and the highest quality retreaded tyres are delivered. This helps fostering the trust of fleet owners in retreading.

Being the pioneers of retreading in India, INDAG provides its retreaders the best-in-class retreading process consultancy services to ensure the highest performance of every tyre retreaded with INDAG tread rubber.

Retreading is a highly technical process and requires a sharp focus on minute details or else the retreaded tyre can result in a failure. Such failures can further lead to the deterioration of fleet owners’ confidence in retreading.

We always encourage our retreading channel partners to follow INDAG’s 10-step retreading process precisely. We extend retreading process audit services to our channel partners at regular intervals, wherein we help them make sure only the right retreading process is followed.

We audit every step of the 10-step retreading process rigorously and suggest changes wherever required, helping our channel partners earn the reputation of premium retreading solution providers.

To ensure the highest quality of a retreaded tyre, one needs to ensure that the correct process is followed with a focus on minute details. It takes the right set of retreading machinery calibrated and maintained as per the advised standard operating procedures to deliver a zero-error retreading process.

INDAG is one of the first companies to introduce cold retreading technology in India and has acquired a great wealth of knowledge regarding the retreading process and machinery over the last 40 years.

We audit the machinery at our retread partner workshops to ensure seamless operations, avoid any breakdowns and produce the highest quality retreaded tyres for fleet owners.

Our technical team follows the best standard operating procedure while auditing the machinery and suggests all necessary resolutions to the problems diagnosed.

We also educate and encourage our retreading partners to upgrade their workshops with the latest technologies and machinery.

INDAG has vast expertise in retreading machinery accumulated over 40 years, based on which we provide machinery consultancy services to our retread partners. We also educate them on the latest technology and machinery that should be installed at their workshops.

A few decades back, when the Indian retreading industry was primarily focused on hot retreading, INDAG was one of the first companies to introduce cold retreading technology in the country, revolutionizing the whole industry.

It was a complete change of technology in terms of product manufacturing as well retreading process and machinery. Today most of the retreaders in India have switched to chamber from bonder for far better curing results.

Technology is an ever-changing process, demanding one to upgrade with the latest of it to stay relevant.

INDAG understands this precisely and always encourages its retread partners to keep upgrading their workshops and improve the retreading quality. As a step further in this direction, we provide consultancy services to our retreading partners for upgrading the workshop. We work closely with the partner and help them with the following processes-

We help our channel partners analyzing the existing machinery and structure of the workshop. We help them find relevant gaps in the existing infrastructure understanding their output requirements.

After analyzing the As-Is model, finding gaps and agreeing on the required upgrades, we further help the partners design their upgraded workshop to achieve the desired output.

We help them analyze the feasibility of executing the upgrades and implementing the To-Be model. It is one of the key deciding factors in analyzing whether the upgrades are worth the results.

Once the partners are confident to go ahead with the upgradation, we advise them on the trusted sources for procurement of the machinery.

If you are new to the industry or you are trying to set up a new-age retreading workshop, it can be a daunting task. Often, we come across retread partners who could not set up a suitable workshop because of the absence of proper guidance and handholding. We aim to minimize every such possibility of a retreading setup going wrong.

Being in the industry since 1978, we understand the needs of retreaders and have the required expertise to provide consulting on setting up a retreading workshop. It includes market assessment & sizing, feasibility analysis, floor planning & designing and machinery sourcing.

We help our channel partners study the targeted market, map competition and assess the opportunity size. It enables the prospect in sizing business potential and making an informed decision on how to enter the market and develop the business.

One of the key risks in starting a business is to assess if doing business is feasible in the targeted market. We help in looking at the feasibility of setting up a workshop in a particular place after analyzing the market potential and anticipating the ability to service a possible customer set with the available capital. It indeed helps in minimizing any unknown risks before starting the business.

Setting up a retreading workshop requires precise planning. It is necessary to set up the workshop in a technical manner to maximize the productivity and efficacy of workflow. INDAG has vast expertise and knowledge base on designing the most efficient and effective retreading workshops. We love to help the prospect channel partners with setting up a world-class retreading workshop.

Retreading is a niche industry; at the same time, it demands high technical know-how to operate. There are not many quality players in the market who manufacture world-class machinery. Over and above, the industry has many unorganized players dealing in the inferior and cheaper versions of retreading machinery. The quality of retreading machinery directly affects the quality of retreaded tyres, and thus cannot be comprised. We make sure that our prospect channel partner procures the best machinery from the trusted sources only.

It is quite evident that retreaded tyres often face a question mark on their quality and trust amongst the fleet owners. Retreading is a very technical process that demands the utmost workmanship with highly functional machinery. The machinery becomes prone to breakdowns due to continuous usage over a while and there can always be unavoidable circumstances that can default the retreading process or its output quality. INDAG understands such scenarios and we take responsibility to help our channel partners in such a situation troubleshooting their challenges to ensure that only the highest quality retreaded tyres are delivered to fleet owners. The following set of services are provided under troubleshooting:

We attend any mechanical or machinery breakdown at the retreading workshop that needs to be resolved to keep the retreading plant up and running. Our service engineer analyses the machinery, mark the problem and suggests a fitting solution to resolve the issue effectively & efficiently.

The biggest hurdle a retreader faces is the retread failure, where the problem is not easily diagnosable. In such cases it is an ardent task to analyze and find the exact cause behind the problem. The rich knowledge base and experience acquired in the last 40 years allow our experts to help our retread partners resolve such complicated issues in the shortest time, avoiding any profound productivity losses.

To understand our Retreading Consultancy Services further kindly reach out to us below.